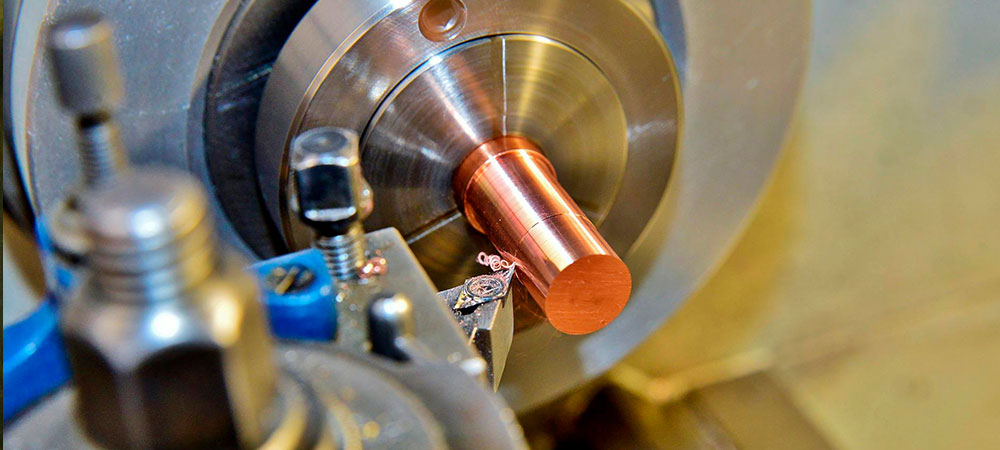

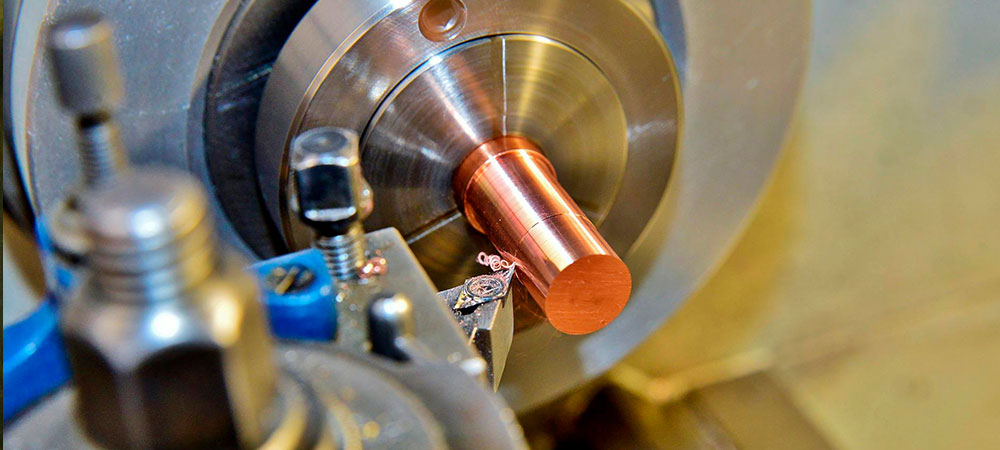

Our Swiss-style machine equipment is a cost effective way to provide extreme accuracy for small parts, long slender parts, and screws. Since Swiss-style operations can produce complex parts in a single operation, production time is decreased. With the adoption of Swiss CNC machines, we can perform multiple complex operations through computer controlled programming, resulting in tighter tolerances, better surface finish, and improved consistency.

Our Swiss-style machines are capable of typical boring, deburring, drilling, knurling, milling, reaming, and turning operations. This type of equipment offers additional capabilities including broaching, deep hole drilling, hobbing, slotting, thread cutting, tapping, thread milling, and thread rolling. They are capable of continuous or high speed machining, utilizing 7 axes and live tooling. We work with steels, aluminum, brass, copper, iron, and titanium materials utilizing Swiss-style machining operations. We can also perform these operations with polymers such as ABS, Acetal, Fiberglass, and Nylon. With Swiss-style machining, we can achieve tolerances as close as ± 0.0003” with part lengths of up to 36” and maximum diameters of 1.25”. Our team has produced connectors, fasteners, fittings, and shafts in prototype, low volume, or high volume batches. While we typically quote on a job by job basis, time may vary depending on the project complexity and timeframe requested.

Our team at Miller Precision Mfg. Ind., Inc. is well versed in both manual and CNC capable Swiss machining operations, supported by a state-of-the-art Tsugami Swiss turning equipment. We’ve performed Swiss-style operations for multiple industries, including precision components for aerospace, electronic, medical, optical, and dental applications. In addition to precision machining, we adhere to stringent certifications, specifications, and industry standards such as ANSI, ASTM, AWS, ISO, QS, and RoHS.

We continue to provide an ever-growing inventory of machinery that will expand your production capabilities, offer extreme precision tolerances, and ensure part quality.

Cnc Turning Services Capabilities

Processes (General Capabilities) | Boring Milling |

Processes (Special Capabilities) | Broaching Hobbing |

Processes (Threading) | External Thread Cutting Thread Milling |

Machinery Axis | 7 Live Tooling |

Equipment Capabilities | CNC Control Capabilities Swiss Screw Machine |

Automation Capabilities | Continuous Machining High Speed Machining |

Materials (Metals) | Alloy Steels Copper |

Materials (Plastic Polymers) | ABS (Acrylonitrile Butadiene Styrene) Fiberglass Reinforced Plastics |

Part Dimension | Min Max |

Outer Diameter | Min Max |

Tolerance (+/-) | ± 0.0003 in |

Additional Capabilities | Assembly Painting |

Production Volume | Specialty Production Shop Low Volume |

Lead Times Available | Quoted on a Job by Job Basis Rush Services Available |

Additional Information

Intended Applications | Machine Components Pins |

Industry Focus | Aerospace Machine Tool |

Industry Standards | ANSI American National Standards Institute Mil-Spec Military Specifications |

File Formats | DXF SolidWorks (SLDPRT,SLDDRW,SLDDRT) STEP |